Plastic has become a bit of a dirty would in the last few years, and it’s easy to see why with the rise of climate change and the amount of plastic waste ever increasing.

However, it doesn’t have to be a dirty word, and if you’re considering starting a business and can’t decide between using metals, plastics or glass, you shouldn’t just discount plastic.

Issues with plastic

Yes, it’s easy to see why there’s a lot of negatives around plastic. In a 2018 article on plastic pollution, it was unveiled that between 1950 and 2015, plastic production had grown nearly 200-fold to 381 million tons per year.

It was also discovered that in 2010, 275 million tons of plastic were wasted globally, which continues to increase, and 80% of the ocean’s plastic comes from land.

A lot of this, however, refers to single-use plastic, and if your business isn’t using this, it does make a large difference. Recycled plastic is something that’s being championed by many companies now, especially after the discovery that only 9% of the world’s plastic was recycled. You, however, could help change that by opting to use recycled plastics, which aren’t single-use either.

Using plastic

You may be wondering why you should use plastic, and how to use. Firstly, it’s very cost-effective, which brings huge advantages with it, allowing you to keep overheads lower and also meet higher demands when it comes to orders – depending on what your product is.

The type of product you produce will also be affected because of various plastic fabrication methods. Because plastic comes in various shapes and sizes, it’s extremely versatile, meaning it’s easier to manipulate into the product you make. You’ll also have to use different tools depending on the method of fabrication.

Plastic fabrication methods include:

Welding

This is achieved by joining together two thermoplastics such as this Kydex 6565 thermoplastic sheet which is used in the manufacturing of airplane interiors to meet certain compliances. This is done by melting the surfaces of each of the thermoplastics and pressing them together to combine them and piece them together into the required shape. Their easily moldable, durable, and fire-resistant properties make them ideal for such important manufacturing projects.

However, the type of plastic will determine what welding equipment you’ll require.

Moulding

High heats and molds are used here to help shape the plastic you’re using into the specific shape. However, there are three different types of plastic molding you can choose from, which include plastic injection moulding, blow molding, and rotational molding.

Compounding

This is also known as blending, and is when you combine two types of plastic, or more, into a mix, before using the melted plastic to turn it into the desired shape at the end of the process.

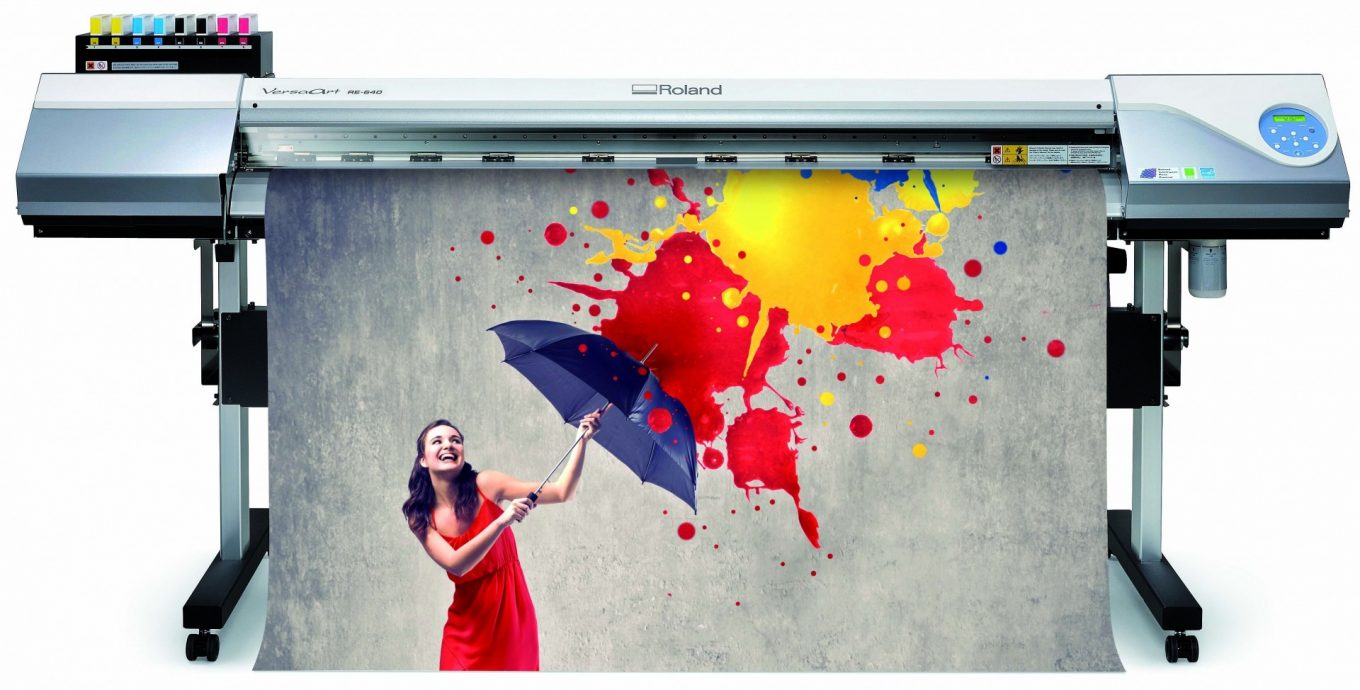

Plastic lamination

This is used to create a plastic barrier along the surface material, using heat and pressure, which is mostly used when improving a product’s aesthetic or durability.

Other methods

The plastic extrusion method is used when creating piping, tubing, or sheeting products, while the plastic foaming method is used for insulation and foam shaping.

Now that you know what there is to know about shaping plastic, you’ll be able to create your products much cheaper, while ensuring they’re more environmentally friendly.

This is an article provided by our partners network. It might not necessarily reflect the views or opinions of our editorial team and management.

Contributed content

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems