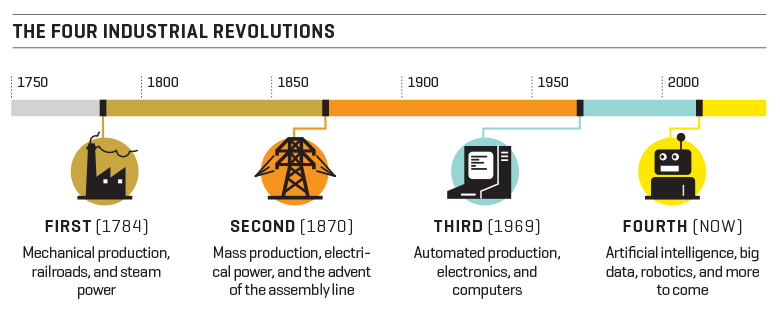

The pace of change in manufacturing today is faster than it ever has been before. The world has seen three industrial revolutions already; first, when textile manufacturers in 18th century Britain mechanized production, second, when Henry Ford created the assembly line in manufacturing automobiles, and third, when automation and computers were first introduced into factories. Technology during these shifts advanced along a linear path. The Fourth Industrial Revolution, the introduction of cyber physical systems, is advancing at an exponential rate.

Technology is moving rapidly and manufacturers are investing heavily because they know that finding new efficiencies will be the only way to stay competitive in the future. The industry is shifting from finding efficiencies by cutting down labor costs (and moving as much as possible to cheaper labor markets), toward a world where highly-skilled workers and highly-automated factories guided by IoT will have the competitive edge. The latest industrial revolution means providing higher quality components at lower prices, while talent and technology will give manufacturers their edge.

When it comes to metrology, new equipment and software are unlocking new capabilities in coordinate measuring machines. Automated coordinate measuring machines, 3D laser scanners, real-time data collection, and software that can predict equipment collisions and adjust errors are all becoming a reality on shop floors across the globe. It’s probably time that you update your CMM measuring machine if you want to keep your technology competitive. In the race to build higher quality components to compete with both lower-cost labor markets and economies like Japan and Germany (which have a lead on automation), North American shops will have to take a close look at their metrology equipment.

Coordinate measuring machines are the cornerstone of your Quality Assurance department and you need technology that’s not just highly accurate but also efficient. While coordinate measuring machines themselves are not very different today than they were ten years ago, new software and equipment has made major strides. Here are just some of the updates you may want to consider, available from metrologists like Canadian Measurement Metrology (CMM):

Multi-sensor Coordinate Measuring Machines – There’s more to today’s coordinate measuring machines that just touch-trigger probes. Touch-trigger probes are precise but slow, but now metrologists use laser scanners in conjunction with touch probes to drastically speed things up and even make automated measurement possible.

Polyworks – Polyworks received a 2017 software update that introduces a suite of new capabilities to speed up your QA process. It’s based on “control-centric reviewing workflow,” which means rapid data collection and real-time collision analysis. It can help you introduce one of the core design principles of Industry 4.0: decentralized decision-making. Ask about Polyworks and software training at metrology shops like CMM for more details.

3D Laser Scanners – 3D laser scanners provide fast, precise measurements and can be used on a portable arm, on a coordinate measuring machine, or on their own. They come in two basic types: lasers scanners and structured light scanners. While laser scanners use guided laser beams to calculate distance, structured light scanners measure using projected patterns of light with a camera.

With these tools, you can bring your shop to a new level of accuracy and efficiency. Speed up inspections and guarantee higher quality components.

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems