Washers are one of the major parts that play a key role in many applications, used as connectors, fasteners, and stability in a fastening system to distribute load. SAE washers have a certain status among various types of washers due to their precision and reliability.

Understanding the benefits of using SAE washers will help decision-makers choose the right component for their specific needs. The distinctive features of these washers make them suitable for specialized applications where accuracy matters.

Understanding Washers

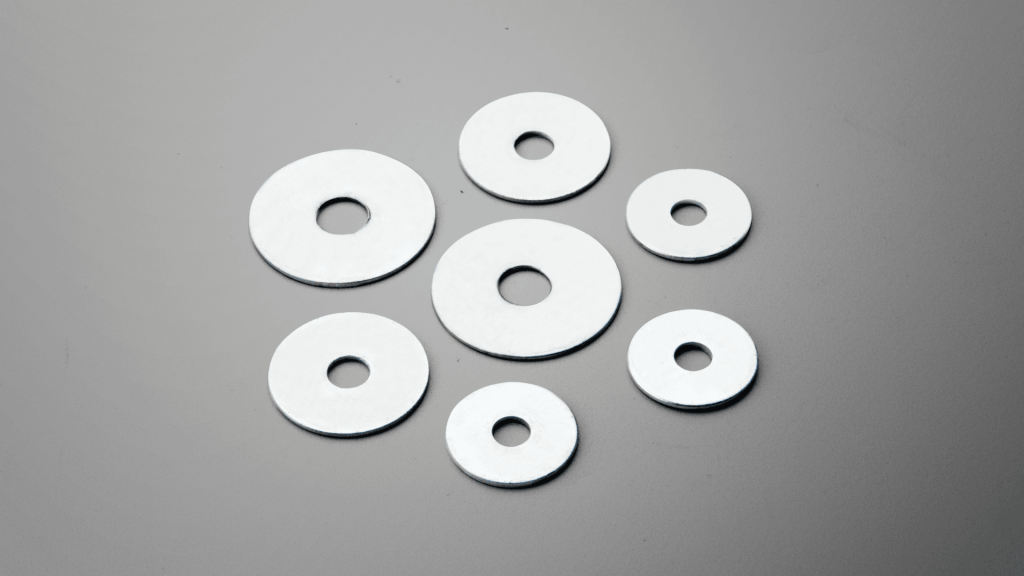

Washers are flat, thin, circular plates with a hole in the middle. They help spread the load of a threaded fastener like a screw or nut. Washers create even load distribution, protect surfaces from damage, and provide a better fit. They also reduce friction and avoid leakage in many applications.

The Basics of SAE Washers

SAE washers — so-called for the Society of Automotive Engineers — are made according to specific industry standards. These washers are accurate and dependable, hence widely used in automotive and industrial applications. The standards maintain the uniformity of dimensions and quality, which is why they are widely adopted in many mechanical applications.

Compare This With Conventional Washers

Another essential variant is the standard washer, more commonly known as USS (United States Standard) washers, which vary in size and thickness. SAE washers tend to be thinner and smaller than USS washers. This variation means that SAE washers are better suited for situations when a more compact fit is necessary or when there is no extra space to spare. Their exact dimensions provide a more secure and controlled fastening for delicate/intricate jobs.

Material Matters

Washer performance depends on the material used to make them. SAE washers are typically constructed of premium metals (for example, stainless steel, carbon steel, etc.). These show high resistance to corrosion and wear, thus increasing durability. The type of material depends on how specific requirements must be met, which can be related to how the product is used (facing external elements) or how it works (for electrically conductive applications).

Uses of SAE Washers

SAE washers are widely used in automotive applications that require precision and reliability. They are also applied in machinery, aerospace, and electronics. Industries where precision is critical. According to the National Institute of Standards and Technology, standardized components like SAE washers help ensure quality and safety across industries. In automotive settings, these washers help to cover secure bolts and nuts to keep components fastened tightly, even with pressure placed on them. In mechanical systems, they provide resistance against loosening caused by vibrations or thermal expansion.

Benefits of SAE Washers

SAE washers are designed for a tight fit in applications with limited space, which is one of their main advantages. Given their standardized dimensions, they are a versatile option, since they’ll offer compatibility with several fasteners. SAE washers are built of such high-quality materials that they can last longer without frequent replacement. They are also resistant to corrosion, making them ideal for environments with moisture or chemicals.

Choosing the Right Washer

Size, material, and application area are a few things that one has to consider for choosing the right washer. To perform its task adequately, a washer should be fitted to a fastener. Then it is necessary to select a suitable material for the environmental conditions and mechanical demands. Stainless steel washers are rust-resistant, while carbon steel washers are sturdy and long-lasting. Being aware of these aspects helps in ensuring that the washer selected coordinates best with the requirements of the task.

Guidelines for Installing SAE Washers

The benefits of SAE washers can only be realized with correct installation. The washer must rest flat against the surface to prevent uneven force distribution and loosening. Getting the washer aligned directly with the fastener is crucial for proper fitment. Do not overtighten, which may cause damage to the washer or the surface. By keeping the installation area clean, the washer performs better and lasts longer.

Routine Maintenance and Replacement

Washers must be checked regularly to ensure the integrity of the fastening system. Identifying wear, corrosion, or deformation before it leads to potential failure is essential for system reliability. Prompt replacement of old or damaged washers preserves the safety and reliability of the device. Having common washers in stock enables easy and quick replacement, significantly reducing downtime due to maintenance.

Conclusion

SAE washers are essential in numerous fields for precision and reliability. Standardized dimensions and high-quality materials make them the preferred choice for specialized applications. Being aware of the distinctions between SAE washers and other varieties enables a wise selection of components for particular tasks. With careful consideration regarding material selection, installation practices, and maintenance, users can reap the full benefits of these key components. With regular maintenance and timely replacement, washers can provide reliable service for a significant time.

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems