Heat poses a silent threat to equipment large and small; it can cause serious damage that leads to costly downtime while reducing the lifespan of the equipment. Machinery and electronics naturally generate heat while in operation, but sometimes heat becomes excessive from overload or broken internal cooling mechanisms.

Heat stress not only degrades materials, but can lead to catastrophic failures. Preventing heat-related damage is a critical aspect of maintaining operational efficiency, safety, and protecting your financial investment. Here are some of the best ways to protect equipment against thermal damage.

1. Use the industry standard

If there’s a widely accepted industry standard for temperature regulation, follow that lead. In most cases, the standard solutions will be well-established and effective when implemented correctly. Don’t try to invent a new method or use something sub-par just to save money. Often, existing standards use highly technical processes that can’t be replicated at a bargain.

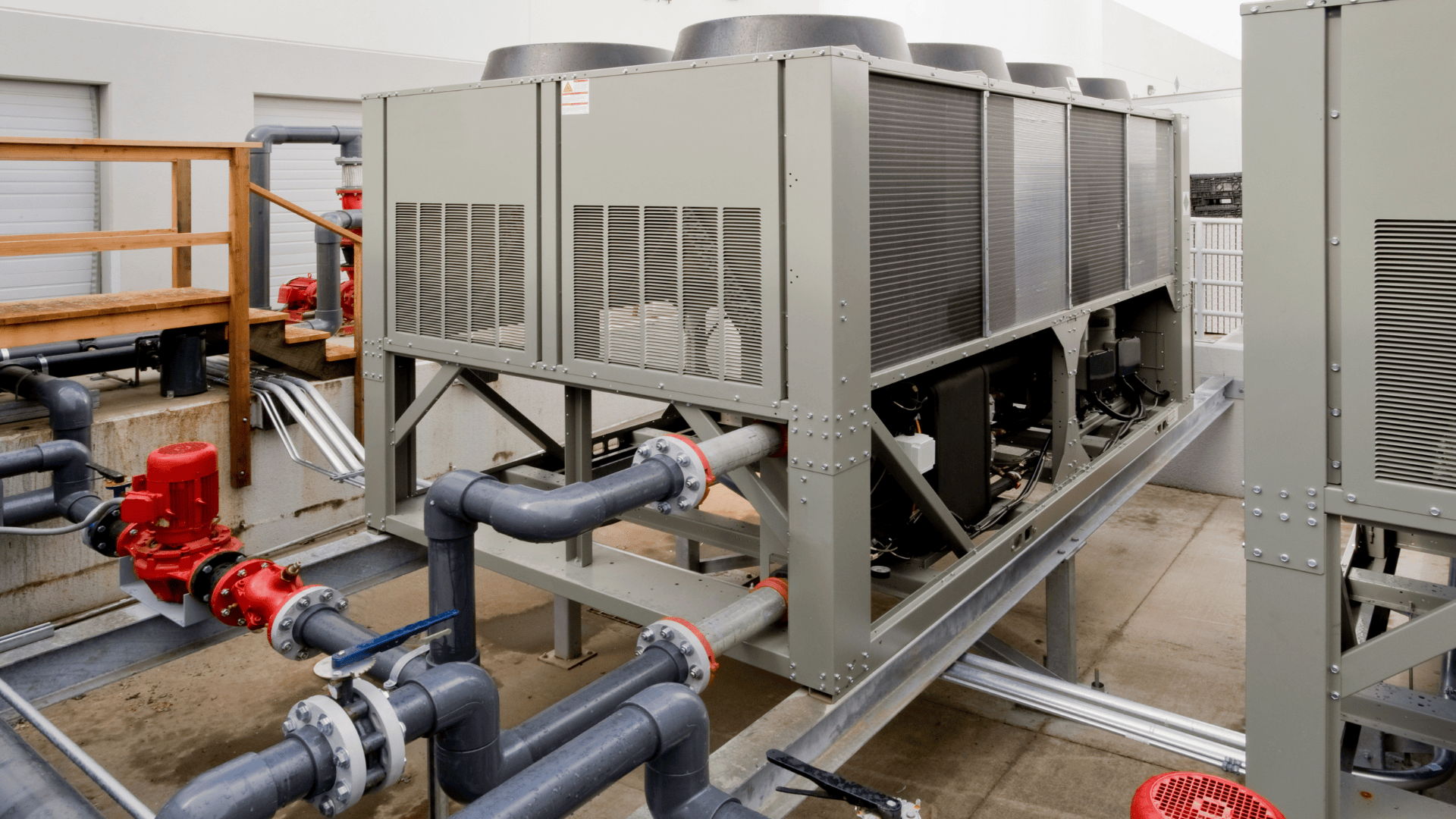

For example, if you need to cool large industrial equipment, you need a chiller. Chillers go through a refrigeration cycle that reduces heat by turning refrigerant into a pressurized gas and then back into a high-pressure liquid. This is a simplified explanation, but it’s a highly specific process that works really well. When a chiller is the standard, other methods, like fans, air conditioning, and evaporative cooling won’t cut it because the cooling range is limited and you can’t control for a precise temperature.

However, these methods might work perfectly in non-industrial applications, like keeping small server rooms cool.

2. Pay attention to airflow

If you’ve ever felt your legs start to burn from using a laptop for too long, that’s a perfect demonstration of what happens when airflow is blocked. Even small pieces of equipment – like laptops – can overheat when air doesn’t flow properly.

In addition to direct cooling systems, proper ventilation and airflow inside the environment are essential. When there’s no airflow, hot air will stick around and begin to impact the equipment after a short period of time. This thermal stress can cause overheating, and it won’t take long for components to break down.

Optimize air circulation in the environment to prevent hot air from collecting around equipment. You’ll need to arrange equipment strategically to allow for natural airflow and use fans to create a constant exchange of air. Whether you use fans or a traditional air conditioner, be sure to change the air filters regularly to prevent clogs from stopping the airflow.

3. Control environmental temperature

In addition to keeping air moving, environmental controls will help to maintain the ideal temperature and humidity levels in the environment. These methods include industrial air conditioning, chillers, and dehumidifiers.

Monitoring ambient temperature and humidity with sensors is critical. High humidity can cause condensation on cold surfaces, leading to corrosion. Excessively dry air can increase static electricity and put electronics at risk. Maintaining a controlled temperature helps equipment operate within the right temperature range, reduces thermal stress, and extends its operational life.

4. Implement proactive maintenance

Predictive and preventive maintenance are your first lines of defense against heat-related equipment damage. Instead of waiting for a component to overheat or fail, a proactive maintenance schedule will help you identify issues early, while you still have time to intervene.

A proactive maintenance strategy includes, but isn’t limited to:

- Regular inspections and cleaning. Visually inspect cooling system components like radiators, fans, hoses, and all connections for signs of damage. It’s equally important to clean regularly, since dust and dirt can accumulate and block airflow.

- Replace hoses and clamps before they fail. Typically, hoses and clamps should be replaced every two years unless signs of damage appear sooner.

- Predictive maintenance. Use technology to monitor equipment and predict potential failures. This includes installing sensors and using infrared heat thermography to detect abnormal hotspots on equipment surfaces

5. Manage operation and loads properly

In addition to cooling system, maintenance, and airflow, it’s also critical to ensure equipment isn’t pushed beyond its capacity. Overloading machinery, pushing it past its designated capacity, or operating it continually without rest periods can create excessive heat that not even the best cooling system can overcome.

Check the manufacturer’s specifications to ensure proper load management and minimize heat generation. All operators should be trained on these specs to prevent breakdowns and extend the life of the equipment.

Protect your assets with heat management

Preventing heat-related damage to equipment requires controlling temperature and humidity by implementing the right cooling systems, conducting preventive maintenance, and prioritizing ventilation. By investing in the proper heat management solutions, you can avoid costly downtime and significantly extend the lifespan of your assets.

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems