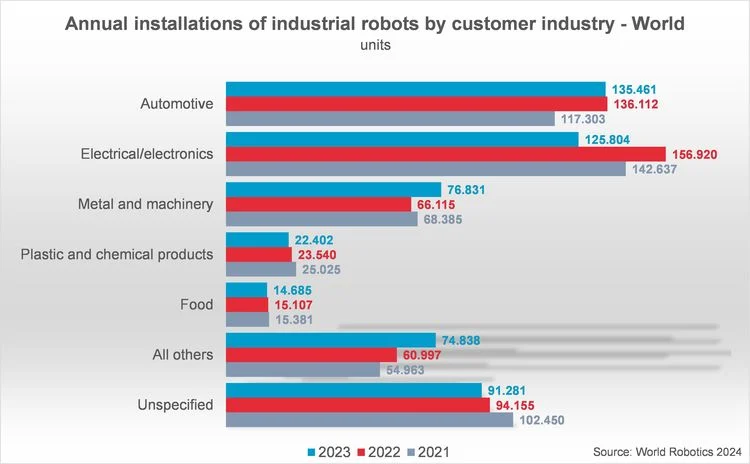

With global robot installations rising 7% yearly in industries engaging from factories and hospitals, businesses leveraging automation gain efficiency, safety, and a competitive edge. But what does this mean for jobs, costs, and the future of work? And how can your business apply its power without leaving human talent behind?

The idea of robots playing a central role in business might sound like something straight out of a sci-fi movie. Yet, what was once pure fiction is now an everyday reality. Across industries, robots are taking on tasks that are too dangerous, repetitive, or time-consuming for humans.

Businesses in sectors from manufacturing and healthcare to retail and logistics are turning to robots for people. The result? Safer work environments, faster operations, and more efficient systems.

Let’s rewind for a moment.

The roots of robotics and automation can be traced back to the Industrial Revolution in 1760. That historical shift transformed how raw materials were handled and how production was organised.

Since then, we’ve moved through several industrial phases, and today we find ourselves in Industry 4.0. With the rise of cloud computing, cyber-physical systems, AI, and lean manufacturing, we are now seeing a manufacturing world driven by intelligent, adaptable, and highly efficient systems.

Robotics and automation have come a long way, and their global adoption is picking up speed. With robot installations expected to grow by 7% annually, and costs becoming more manageable, more businesses are jumping on board.

What Makes a Robot a Robot?

At its core, a robot is a programmable machine capable of carrying out complex actions automatically. According to the International Organization for Standardization, a robot is “an automatically controlled, reprogrammable, multipurpose manipulator” operating on three or more axes.

Future Learn expands on this, defining robotic systems as tools that are interconnected, interactive, cognitive, and physical. They can perceive their surroundings, process information, and act using computer algorithms and physical actuators.

Three things set robots apart:

- Mechanical structure – the physical body that interacts with the world.

- Electrical components – sensors, processors, and actuators that drive behaviour.

- Programmability – the ability to follow, learn, or adapt instructions.

The roots of robotics stretch back further than you might think. Aristotle once imagined ‘automated tools,’ while Leonardo da Vinci sketched designs for a mechanical knight—an early glimpse into the concept of humanoid machines.

Fast forward to the 20th century, and robotics took a giant leap forward with the Industrial Revolution. The shift from manual labour to mechanised production laid the groundwork for modern automation. Factories adopted conveyor belts, hydraulic systems, and eventually, programmable machines.

Key milestones in robotics:

- 1954: George Devel invented Unimate, the first industrial robot, a hydraulic arm used in car manufacturing.

- 1980s: Robotics expanded beyond factories. Honda’s ASIMO showcased humanoid capabilities, while Roomba brought robots into homes.

- 2000s: AI transformed robotics, enabling machines to learn, adapt, and interact naturally. Surgical robots, drones, and warehouse automation became mainstream.

- 2010s-Present: Cobots (collaborative robots) emerged, designed to work safely alongside humans. AI-driven perception and decision-making are now pushing robotics into new frontiers.

Types and categories of modern robots

Today, robots are everywhere. And they aren’t all built the same. Based on function and design, they can be grouped into several categories:

- Autonomous Mobile Robots (AMRs): These smart robots can navigate spaces without human input, using sensors and onboard software.

- Automated Guided Vehicles (AGVs): Used in warehouses, these follow fixed paths to move goods around.

- Articulated Robots: Multi-jointed arms, often used for welding, material handling, or packaging.

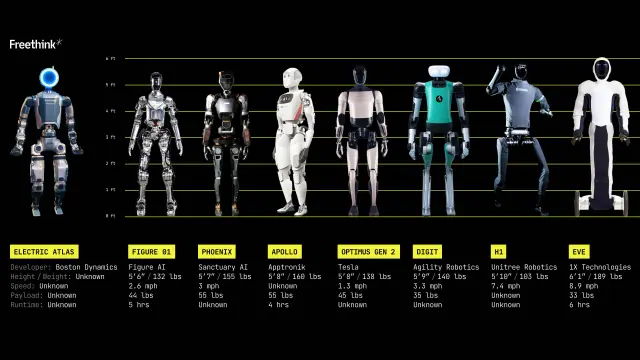

- Humanoids: Designed to mimic human appearance or behaviour, useful in customer service roles.

- Cobots: These work collaboratively with humans in shared spaces, often handling repetitive or heavy tasks.

- Hybrid Robots: Combining features of other types, like an AMR fitted with a robotic arm for flexible warehouse tasks.

How robotics is transforming industries

1. Manufacturing

Manufacturing is one of the earliest and most extensive adopters of robotics. On factory floors around the world, robots perform repetitive and dangerous tasks with speed and precision. Activities like welding, painting, assembling, and packaging are now mostly handled by machines, leading to fewer errors and greater efficiency. These robots not only accelerate production timelines but also reduce the risk of workplace injuries by taking over physically demanding or hazardous operations.

For example, Tesla uses hundreds of industrial robots in its Gigafactories to automate key aspects of electric vehicle production, from stamping and welding to final assembly, allowing for consistent quality and increased throughput.

2. Healthcare

Robotics in healthcare is transforming the way surgeries, rehabilitation, and medication management are carried out. Surgical robots allow doctors to perform minimally invasive operations with enhanced precision, which often results in quicker recovery times for patients. In rehabilitation, wearable robotic exoskeletons assist individuals with mobility impairments, helping them regain physical functions. In hospitals, pharmacy robots are being used to sort and dispense medications with near-perfect accuracy, reducing the risk of human error.

A prominent example is the Da Vinci Surgical System, widely used in hospitals worldwide. It assists surgeons in performing delicate procedures such as prostatectomies and cardiac valve repair with improved dexterity and vision.

3. Logistics

In the logistics sector, the use of robotics has given rise to what are now called “smart warehouses.” Companies are deploying Autonomous Mobile Robots (AMRs) to navigate warehouse aisles, sort packages, pick items from shelves, and transport goods. These systems improve inventory accuracy, shorten delivery cycles, and significantly cut down on manual labour.

A great example is Amazon’s use of Kiva robots (now part of Amazon Robotics), which travel around massive fulfilment centres, lifting and moving entire shelving units to human workers, dramatically increasing efficiency and order fulfilment speed.

4. Agriculture

Modern farming is being revolutionised by robotics, with machines taking over tasks once handled manually. Robotic systems are now used for planting, crop monitoring, irrigation, and harvesting. AI-powered drones survey fields to detect diseases and nutrient deficiencies, while automated irrigation systems ensure crops receive the right amount of water. These technologies contribute to sustainable farming by reducing resource waste and boosting yield.

An example is Ecorobotix, a Swiss company whose solar-powered robotic weeder uses AI to identify and spray individual weeds with precision, significantly cutting down on herbicide use and protecting the surrounding crops.

5. Construction and Mining

In high-risk environments like construction sites and mines, robots are increasingly taking over tasks that are hazardous for human workers. These include operating in confined spaces, handling heavy materials, and conducting inspections in unstable areas. Robotic systems not only increase worker safety but also ensure tasks are carried out with greater precision and consistency.

One example is the use of Boston Dynamics’ Spot robot in construction projects. Spot can navigate rugged terrains, inspect structural elements, and monitor site progress, all while keeping human inspectors out of dangerous or inaccessible areas.

Case study: Ocado – Transforming grocery retail with robotics and AI

Ocado, a British online-only supermarket, has redefined the grocery industry through its innovative use of automation and robotics. Founded in 2000, the company began as a traditional online grocer but gradually evolved into a technology-led business that builds automated fulfilment centres for itself and partners across the globe.

Challenge:

Online grocery shopping presents unique logistical challenges—products are perishable, order volumes fluctuate daily, and delivery windows are tight. Ocado needed a way to fulfil thousands of customer orders with accuracy, speed, and minimal human error, all while keeping operational costs sustainable.

Solution- The Ocado Smart Platform (OSP):

Ocado developed the Ocado Smart Platform, an end-to-end solution combining robotics, AI, and cloud computing. At the heart of this system are highly automated warehouses operated by a fleet of robots that move across a giant grid system. These robots communicate via a 4G-based wireless network, coordinating movements every tenth of a second.

Each robot can pick up a storage bin containing grocery items and bring it to a human or robotic picking station. Algorithms optimise robot movement to prevent traffic and improve picking speed. Advanced machine learning tools forecast demand, manage stock, and optimise delivery routes.

Impact:

- Efficiency: One Ocado fulfilment centre can process over 200,000 orders a week, with robots completing up to 65,000 picks per hour.

- Labour savings: Robotics have significantly reduced manual labour needs in packing and sorting, allowing human staff to focus on quality control and exceptions.

- Scalability: The technology has been licensed to international partners, including Kroger in the US and Coles in Australia, showcasing its global applicability.

- Innovation leadership: Ocado has been recognised as one of the most innovative retailers worldwide, with a strong focus on continuous R&D in robotics and AI.

Will robots take our jobs?

It’s a big question and one often dramatised by headlines. But the answer isn’t a simple yes or no.

A study by MIT found that each additional robot per 1,000 workers reduced wages slightly and led to job losses in some sectors, especially manufacturing. On the other hand, robots are also enabling job creation in tech, maintenance, and operations.

The real issue lies in how we adopt robots. Used wisely, they can complement human labour, not replace it. They can take over dull or dangerous tasks, freeing people to focus on problem-solving, innovation, and strategy.

Still, the effects are uneven. Young, less-educated workers, and those in lower-income brackets, are more vulnerable to automation. It’s important that businesses and policymakers focus on retraining and education to help the workforce transition.

The future: Where are robots headed next?

We’re at a crossroads. Automation and robotics are no longer optional, they’re a necessity for staying relevant and efficient in the modern economy. But as we welcome these technologies into our businesses, factories, and homes, it’s vital to keep people at the centre of innovation.

So, where is all of this headed?

- Smaller, smarter robots will become accessible to small businesses.

- Cobots will dominate manufacturing, working side-by-side with humans.

- Humanoid and service robots will appear in schools, retail, and homes.

- Spatial AI will enable robots to understand environments in 3D, improving their ability to navigate and interact.

The International Federation of Robotics (IFR) notes that the future lies in flexibility, collaboration, and sector-specific innovation. With technologies advancing and costs coming down, robotics is no longer just for big corporations, it’s becoming an essential tool for businesses of all sizes.

Dinis Guarda is an author, academic, influencer, serial entrepreneur, and leader in 4IR, AI, Fintech, digital transformation, and Blockchain. Dinis has created various companies such as Ztudium tech platform; founder of global digital platform directory businessabc.net; digital transformation platform to empower, guide and index cities citiesabc.com and fashion technology platform fashionabc.org. He is also the publisher of intelligenthq.com, hedgethink.com and tradersdna.com. He has been working with the likes of UN / UNITAR, UNESCO, European Space Agency, Davos WEF, Philips, Saxo Bank, Mastercard, Barclays, and governments all over the world.

With over two decades of experience in international business, C-level positions, and digital transformation, Dinis has worked with new tech, cryptocurrencies, driven ICOs, regulation, compliance, and legal international processes, and has created a bank, and been involved in the inception of some of the top 100 digital currencies.

He creates and helps build ventures focused on global growth, 360 digital strategies, sustainable innovation, Blockchain, Fintech, AI and new emerging business models such as ICOs / tokenomics.

Dinis is the founder/CEO of ztudium that manages blocksdna / lifesdna. These products and platforms offer multiple AI P2P, fintech, blockchain, search engine and PaaS solutions in consumer wellness healthcare and life style with a global team of experts and universities.

He is the founder of coinsdna a new swiss regulated, Swiss based, institutional grade token and cryptocurrencies blockchain exchange. He is founder of DragonBloc a blockchain, AI, Fintech fund and co-founder of Freedomee project.

Dinis is the author of various books. He has published different books such “4IR AI Blockchain Fintech IoT Reinventing a Nation”, “How Businesses and Governments can Prosper with Fintech, Blockchain and AI?”, also the bigger case study and book (400 pages) “Blockchain, AI and Crypto Economics – The Next Tsunami?” last the “Tokenomics and ICOs – How to be good at the new digital world of finance / Crypto” was launched in 2018.

Some of the companies Dinis created or has been involved have reached over 1 USD billions in valuation. Dinis has advised and was responsible for some top financial organisations, 100 cryptocurrencies worldwide and Fortune 500 companies.

Dinis is involved as a strategist, board member and advisor with the payments, lifestyle, blockchain reward community app Glance technologies, for whom he built the blockchain messaging / payment / loyalty software Blockimpact, the seminal Hyperloop Transportations project, Kora, and blockchain cybersecurity Privus.

He is listed in various global fintech, blockchain, AI, social media industry top lists as an influencer in position top 10/20 within 100 rankings: such as Top People In Blockchain | Cointelegraph https://top.cointelegraph.com/ and https://cryptoweekly.co/100/ .

Between 2014 and 2015 he was involved in creating a fabbanking.com a digital bank between Asia and Africa as Chief Commercial Officer and Marketing Officer responsible for all legal, tech and business development. Between 2009 and 2010 he was the founder of one of the world first fintech, social trading platforms tradingfloor.com for Saxo Bank.

He is a shareholder of the fintech social money transfer app Moneymailme and math edutech gamification children’s app Gozoa.

He has been a lecturer at Copenhagen Business School, Groupe INSEEC/Monaco University and other leading world universities.