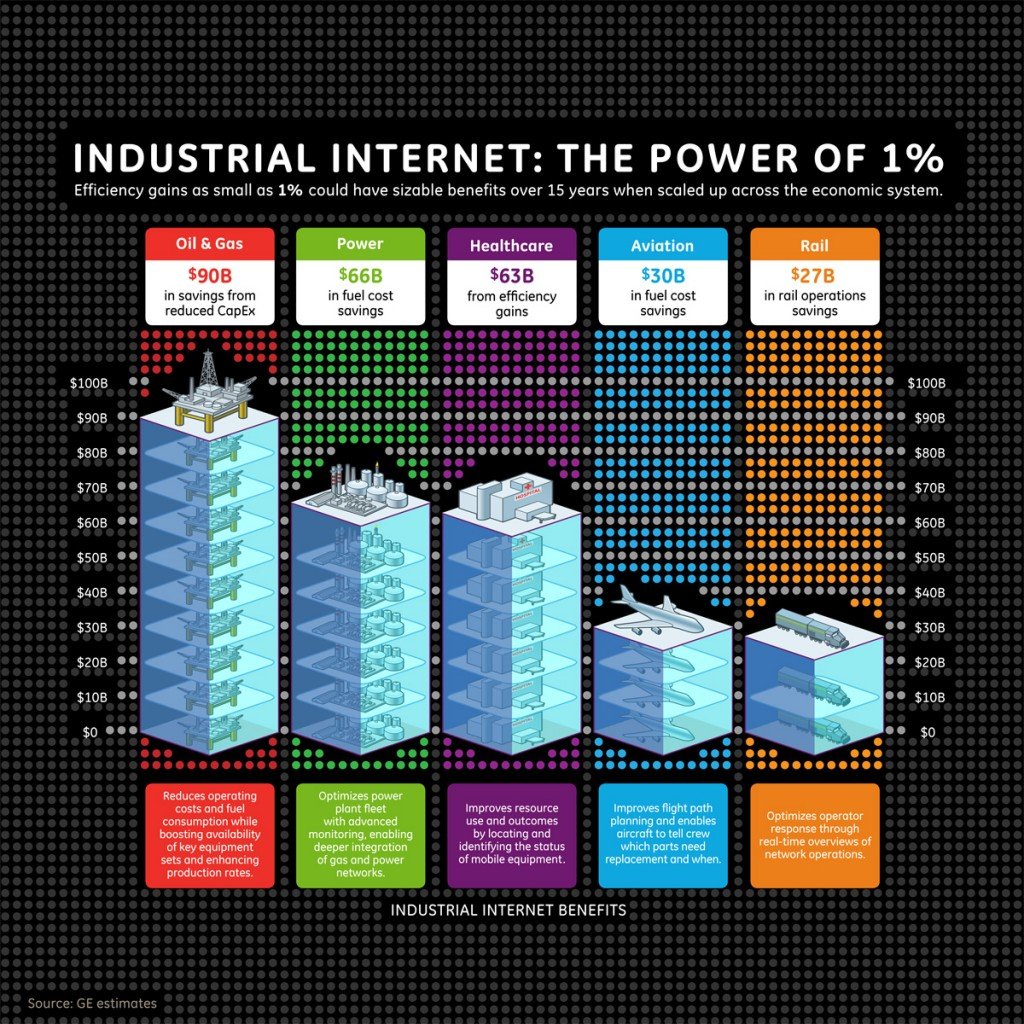

Workplace productivity affects the bottom line of many companies. Unforeseen mishaps and unplanned downtime in the work environment can accelerate across the ecosystem and affect the economy. This was recently confirmed by GE’s Chief Economist Marco Annunziata. With the Bring Your Own Device revolution already starting to impact businesses, future technology will enable workers to store and access maintenance information on simple handheld devices, brainstorm repairs with colleagues, and even monitor and talk to equipment themselves. There will be a proliferation of increased machine-human collaboration.

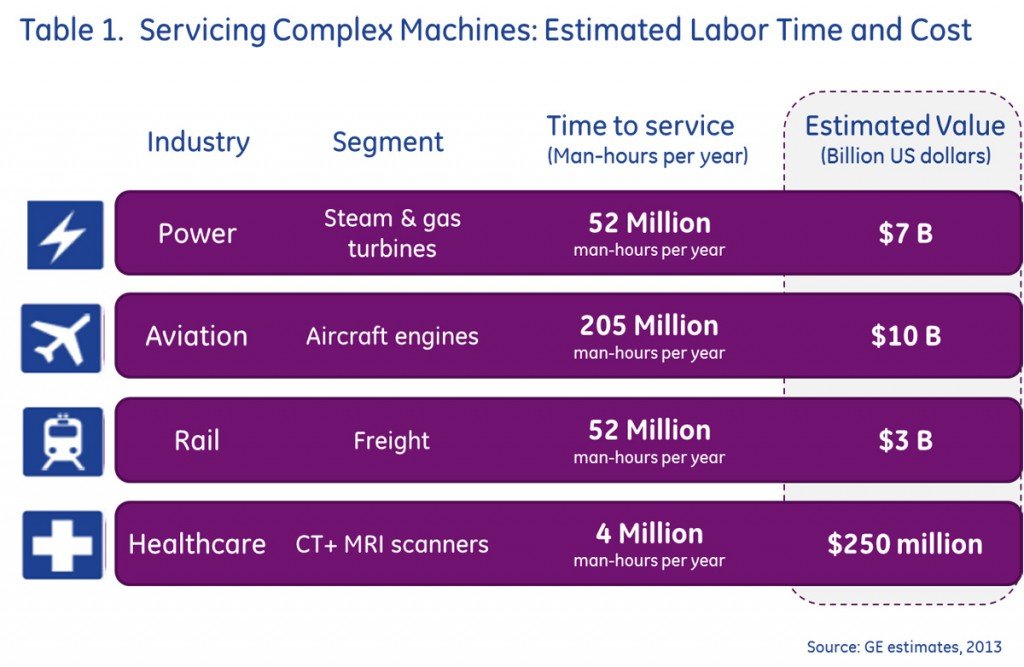

Annunziata and Peter C. Evans, director of global strategy and analytics at GE have collaborated on a new report detailing how the Industrial Internet, predictive analytics and new machine-human collaboration in the workplace can significantly boost productivity, create new jobs and skills, and minimize unplanned downtime in major industries. The increasing trend of digitization and connectivity between man and machine will reduce downtime in the industrial process and will lead to an increase in productivity and an increase in the creation of new rules.

Industrial Internet@Work, makes a case for a new way of unleashing the power of information in the workplace. As information becomes more intelligent, the future of work will be transformed and a new, more highly skilled workforce will emerge. Workers will be able to spend more of their time in higher value-added activities, while upgrading their knowledge, skills and experience at a much faster pace. New digital and software tools will create a more efficient and productive way to interact with machines, increasing collaboration and faster information sharing.

Digitization empowers businesses to work and react “in the now”. Workers can respond in real time to the needs of the businesses. Imagine a future where maintenance teams rely on big data and are in sync with the machines that provide them with that information. That is what the new industrial Internet is all about.

If you thought working in the manufacturing industrial sector meant being covered in dirty overalls, think again. Apart from new jobs and boosting economic growth, someone has to manage all the new technologies that the industrial Internet brings. We can expect to see roles like digital mechanical engineers, user interface experts, data scientists and business operations data analysts. All of them will require new technical skills and contribute to greater workplace efficiency. The existing workforce meanwhile will become fluent in emerging technologies while new workers will be trained to contribute to specialized scientific and technical skills.

Annunziata and Evans reassure us that redundancies will not be a major factor to worry about. Instead it is up to companies to educate workers and teach them the new necessary skills. Annunziata makes the point that “a new, highly-skilled workforce will emerge as the Industrial Internet is poised to have a significant impact.

We can expect to see these changes being implemented over the next 3 to 5 years. It’ll be interesting to observe what the data driven industrial landscape does to the economy, recruitment, education and innovation especially since many manufacturing companies are turning to servitization.

To learn more please view the full report.

image credit via GE

Hayden Richards is Contributor of IntelligentHQ. He specialises in finance, trading, investment, and technology, with expertise in both buy-side, sell-side. Contributing and advising various global corporations, Hayden is a thought leader, researching on global regulatory subjects, digital, social media strategies and new trends for Businesses, Capital Markets and Financial Services.

Aside from the articles, interviews and content he writes for IntelligentHQ, Hayden is also a content curator for capital markets, analytic platforms and business industry emerging trends. An avid new media explorer Hayden is driven by a passion for business development, innovation, social business, Tech Trading, payments and eCommerce. A native Trinidadian, Hayden is also a veteran, having served with the Royal Air Force Reserves for the past 10 years.

Follow Hayden on Twitter @HaydenARichards, linkedin.com/haydenhrichards and http://www.scoop.it/u/hayden-richards