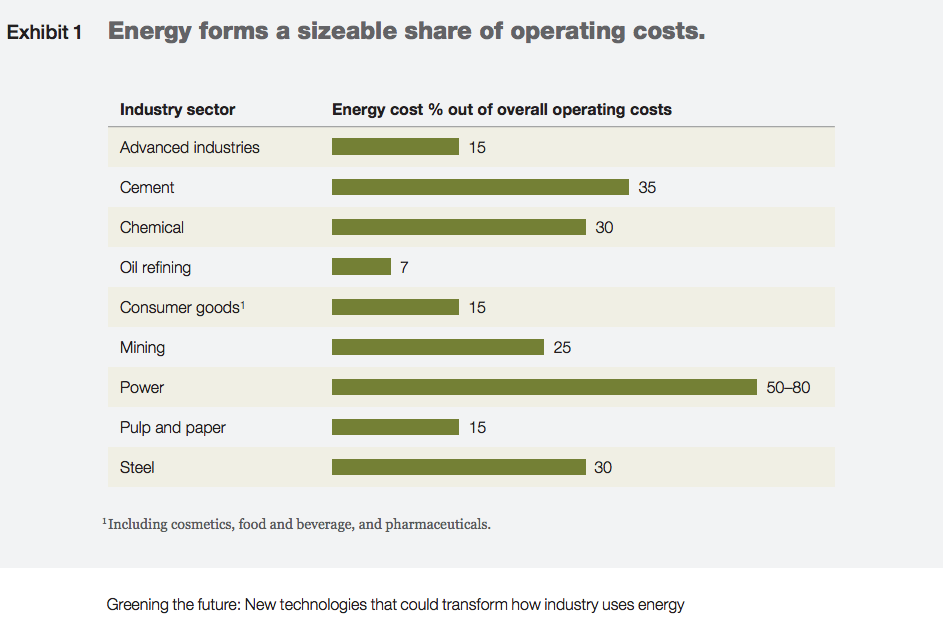

The demand for energy on a global scale is increasing, driven by rises in wealth and population. It is anticipated that energy consumption worldwide will increase by 25% between the current time and 2030. Meanwhile there are major concerns about greenhouse gases and the environment that are leading to organisations and governments questioning the production and use of energy. Energy efficiency is likely to play an important role in the future to make sure that we all have the energy that we need. Energy is a major cost for organisations. A recent report from McKinsey identified that this makes up a sizeable component of operating costs.

Carrying out analysis for McKinsey, Harsh Choudry, Mads Lauritzen, Ken Somers and Joris Van Niel (2015) argue that:

“Since the turn of the 21st century, energy costs have risen steadily. Even when prices have fallen, as happened most dramatically with oil from 2014 to 2015, such rapid swings can be difficult for companies to cope with.”

This means that energy efficiency really makes sense, since energy efficiency helps to directly counter the price stability issues.

Some organisations spend as much as third of their operating costs on energy. This is true of mining industries as well as cement, chemicals and metal industries. In addition to that in areas where costs of hiring people are cheaper, energy costs are also usually greater.

The analysis carried out by McKinsey Analysts demonstrated that operational improvements may be helpful in cutting back on the use of energy by anywhere between 10 to 20%. However, placing funding into energy efficient technology brings considerably greater benefits, with reduction levels possible of 50% or greater.

The research showed that it is by no means unattainable to reduce energy usage very significantly, particularly in the manufacturing sector which is argued to comprise 50% of all global energy consumption. This would have benefits economically for organisations, but also for the environment as well. Overall the research found that the use of new and innovative approaches could help to save in excess of $600 billion per year for industry.

The McKinsey report, based on the research titled: Greening the future: New technologies that could transform how industry uses energy, outlines a total of 33 different innovations which could be highly beneficial in reducing the energy that industry needs to use.

There are innovations listed across nine different categories. The categories include advanced industries, cement, consumer goods, mining, oil refining and chemicals, power, pulp and paper, steel, and general types of innovations. In the majority of cases the technology is already on the market. The only thing that remains left for organisations to do is to work out which are best for them to implement and determine how they can be put to use, to keep making efficiencies for years to come.

McKinsey has outlined five core principles of resource productivity to help with these matters. The first of these is that organisations have to think lean. On this, it is argued that thinking lean and thinking green are quite similar in some ways, and there are definite synergies between the two. The second is thinking about limits. In this regard the organisation should try to strive towards the lowest possible level of energy that might be needed to tackle a set process. The goals should be stretching but realistic for this. In doing this it is possible to come up with creative and innovative approaches that can reduce the amount of energy needed. The third area to consider is profit per hour.

McKinsey suggests that profitability should be the major aspect of the decision making here, looking at the environment and possible throughput.

The fourth aspect is to take a holistic approach. With this it is recommended to consider improvements that can be made to attitudes, mind-sets and behaviour as well as management to make sure that the change is bedded in. Finally, it is argued that thinking circular is necessary where organisations step away from a linear approach. In adopting all of these kinds of changes organisations may be able to become more savvy about how they use energy. This should be a goal for every organisation that wants to be highly effective.

Paula Newton is a business writer, editor and management consultant with extensive experience writing and consulting for both start-ups and long established companies. She has ten years management and leadership experience gained at BSkyB in London and Viva Travel Guides in Quito, Ecuador, giving her a depth of insight into innovation in international business. With an MBA from the University of Hull and many years of experience running her own business consultancy, Paula’s background allows her to connect with a diverse range of clients, including cutting edge technology and web-based start-ups but also multinationals in need of assistance. Paula has played a defining role in shaping organizational strategy for a wide range of different organizations, including for-profit, NGOs and charities. Paula has also served on the Board of Directors for the South American Explorers Club in Quito, Ecuador.